SAP S/4HANA: A Digital Supply Chain and Intelligent Enterprise

SAP S/4 HANA: A Digital Supply Chain and Intelligent Enterprise

Introduction

The goal of many enterprise organizations is to conceive, build and deliver an innovative product to customers at the right time and right price. This involves a chain of events, which need to be perfectly orchestrated and then repeated over and over again. This requires many solutions functioning in an intelligent and coordinated way to ensure the organization achieves its goals. SAP has multiple solutions available, which enable an organization to build a supply chain digitally. Let’s touch upon some of them in this Blog article.

This Blog post will help Pre-sales and Business experts, who need to possess a broad understanding of many SAP solutions allowing them to evaluate customer situations and propose an appropriate SAP solution. In fact, they need to orchestrate SAP solutions as a Digital Supply Chain, to satisfy customer’s requirements.

Three key pillars of any product organization can be shown as follows:

Research & Development and Engineering the Product

In Process Industries, the end-product is typically a compound or solution (for example, different shades of paint in paint industry) based on different formulations using different ingredients. Developing such recipes for different end products is a huge R&D exercise. Managing such specifications, formulations and other such information digitally in central systems helps the R&D and Engineering teams’ organization. SAP Recipe Development can handle these and it also helps in streamlining the formulations, real-time simulations, define equipment requirements and all related needs around R&D.

R&D Innovations require collaboration with suppliers and customers on a real time team work basis. SAP S/4HANA Cloud for Intelligent Product Design solution offers a collaboration platform for such needs. It has features to exchange product data, documents, Bill of Materials and it also has workflows to control data/document movements.

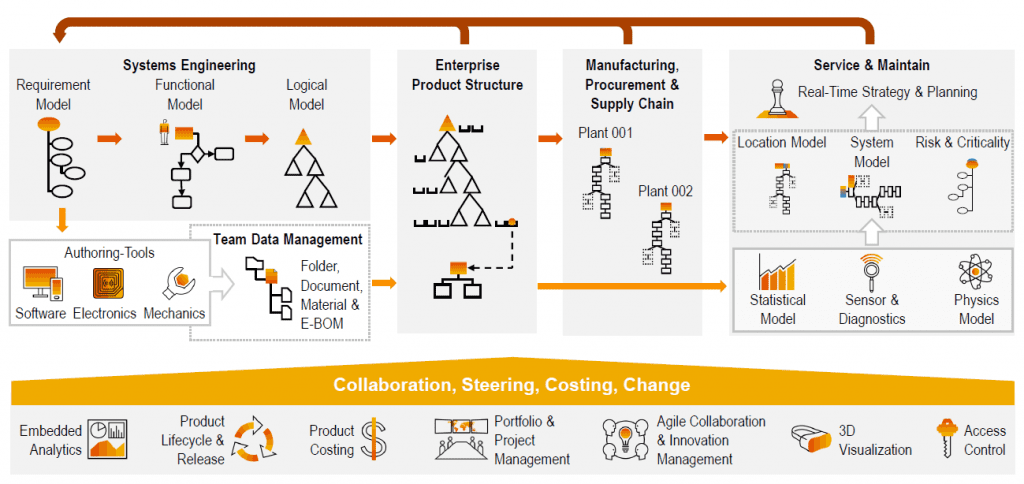

In discrete manufacturing industries, the end-product is typically a physical object made of iron, aluminium or other such materials. R&D in these industries involves visualising a product, adhering to physical attributes such as shape, size etc…. The challenges here are entirely different from the ones in Process Industries (talked above). The diagram below in Exhibit-2 shows the product life cycle complexity in a nutshell. Product visualization is an important aspect of designing a product. Also creating holistic definitions for complex products is important. SAP Engineering Control Centre and SAP 3D Visual Enterprise are solutions to handle these requirements.

Managing costs for New Product Developments, and customer specific engineered products, is very important for an organization. It is natural that organizations would like to minimize the cost of products, early on at the stage of development itself, to understand the cost drivers and simulate the cost for various levers that influence product cost. SAP Product Lifecycle costing is a solution that handle these requirements.

Mainly in Process Industries, and also at times in Discreet manufacturing industries, there are quite a few legal regulations that comes into play. Some of these require attention at the time of product development and some after the product is manufactured. These require credible auditable data captured, especially during the development stage. SAP S/4HANA for Product Compliance is a solution that handles these requirements.

R&D and Engineering a product is a large program sometimes running into many years. It becomes complex when multiple products are in concurrent development. Any organization that constantly innovates new products, must continuously collect ideas, evaluate them and document the most appropriate ones to turn them into products. Then comes:

- the tasks of launching them as projects

- assigning skilled resources

- allocating budgets

- controlling their costs

- ensuring collaboration with suppliers and third parties as needed

- ensure compliances

- manage to bring out a new product for market launch.

SAP Portfolio and Project Management is a solution that handles the entire set of requirements, we mentioned above.

Plan and Manufacture:

Providing the product at the right time, price and place in terms of customer requirements, needs a well-oiled supply chain. It involves the following:

- Developing accurate statistical forecasts for short-term and mid-term demand

- Ensuring an optimum level of inventory (finished goods and raw material) to satisfy customer demands and manufacturing requirements

- Having an optimal business plan to ensure revenue growth and market share

- Automate manufacturing processes and resources to manufacture products efficiently and of good quality

- Gather manufacturing data and gain insights to ensure lower operational costs of manufacturing, across multiple plants/geographies

SAP Integrated Business Planning is a solution that handles most of the planning related requirements. Its Sales and Operations Planning functionality provides a cross-departmental plan which balances inventory, profitability and customer service levels. Inventory optimization functionality provides optimal inventory levels which also provides a buffer to meet unexpected demands. The Forecasting and Demand management function, provides short term, midterm and long-term forecasting based on demand sensing and statistical forecasting abilities.

SAP Manufacturing Execution is a solution that digitizes manufacturing processes. It integrates the business systems in a cost efficient and resource efficient manner. Based on Industry 4.0 technologies, such as Internet of Things (IoT), it helps to improve operational visibility with near real time information. Using near real time data, it helps to identify and resolve product quality and productivity issues quickly. It has abilities to meet individualization requirements of products and still maintain quality, productivity and margins in products.

SAP Manufacturing Insights is a solution that gathers data based on IoT. It is integrated with SAP Cloud Platform to provide holistic analytics across all manufacturing operations. It has preconfigured industry-standard manufacturing Key Performance Indicators (KPI) and also provides for building organization specific KPIs. It has abilities to allow businesses to build customer specific processes for planning, execution, maintenance and quality. It provides for global visibility of manufacturing KPIs across all the plants segmented by site, regional or at a global level.

Transport and Delivery:

The transportation and delivery of goods to the customer poses its own challenges to every organization. It varies from organization to organization depending on the type of products, customers, demand, geographies, transportation modes and distribution network. The following three key areas are relevant in this context:

- Handling and managing the transportation units in the Yard

- Organizing the manufactured products in warehouse and shipping them efficiently

- Ensuring the shipment reaches the customer, whatever the mode of transport might be

SAP Yard Logistics is a solution that provides a link between the distribution & transportation operations and the warehouse. It has functions to streamline planning, execution and settlement of yard tasks with full integration into back-end processes. It handles IoT based data capture. It is simple to adapt yard processes for different transportation means and yards. It helps to efficiently utilize workforce and assets in yard. It has integration with both SAP Transportation Management and SAP Extended Warehouse Management solutions. It also has a function for Gate-IN and Gate-Out Processes of transportation units. The following exhibit-3 brings the reader to a context of this solution:

SAP Extended Warehouse Management is a solution that handles all the operations related to tasks within a warehouse. It has functions to coordinate the selection of correct items from warehouse racks, packing of the products, staging of the packages to relevant loading areas and enabling the loading operations. It has functions to automate warehouses by integrating the material handling equipment and data collection devices. It also provides for product returns handling.

SAP Transportation Management is a solution that provides for freight, fleet and logistics management to get real time visibility into domestic, as well as global, transportation across all transportation modes such as road, rail, air and sea. It has functions to manually plan or map-based plan or automated planning and dynamic re-planning options. It can track and manage driver resources. It can build pallets with rule-based optimization. It can automatically update freight documents and truck information. It can handle freight costing and settlement. It also has integration with SAP Order management.

Summary

It is imperative to have a seamless and digitally connected supply chain from conceiving a product until its final delivery to customers, to run a profitable organization and to beat the competition. SAP has provided a variety of intelligent and connected solutions to handle each stage efficiently. They provide a lot of exciting opportunities, for Consultants and Pre-Sales experts to build their capabilities and orchestrate an end-to-end process according to customer needs, using these solutions and components. In essence, we may confidently say, “Building a digital supply chain helps to build an Intelligent Enterprise”.

Author : Ravi Srinivasan , SAP Alumni

Need to hire SAP Integration resources?

Looking for SAP Integration work?

Get in touch with Eursap – Europe’s Specialist SAP Recruitment Agency