SAP EWM – Enhanced Goods Receipt Reversal Functionality – Allow GRR for single inbound deliveries

SAP EWM – Enhanced Goods Receipt Reversal Functionality – Allow GRR for single inbound deliveries

Improvement:

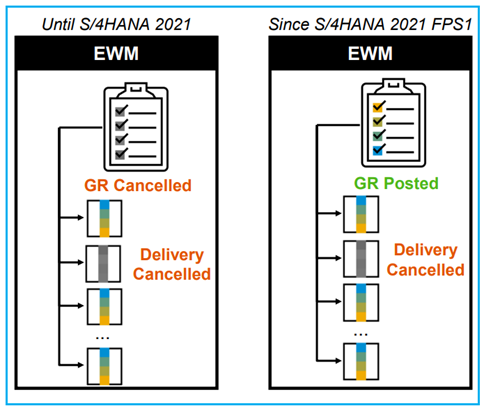

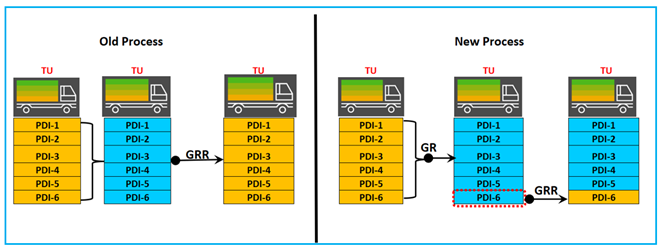

From SAP S/4 HANA 2021 FPS01, SAP has delivered a major improvement in the area of Goods Receipt Reversal (aka GRR) for Single Inbound Deliveries. When GR is posted together for multiple inbound deliveries having a trailer (Transportation Unit) assigned to deliveries, this results in a single EWM warehouse document for the Goods Movement (GM). Currently, GR cancellation is limited to an all-or-nothing principle on GM document level, i.e. an item of a GM document can only be cancelled if all other items in the same GM document are cancelled as well.

Because of this limitation, SAP didn’t support the ability to cancel goods receipts for a single inbound delivery in case the original posting multiple deliveries were involved. Although there are some work-arounds that were provided over time, with this development the GR process itself will remain unchanged and can only be extended to allow partial cancellation for inbound deliveries – even if GR was posted together with other deliveries in one GM document.

Benefit:

With the release of S4 HANA 2021 FPS1, the new enhancement a partial GR cancellation will be supported via SAP note 3087486 – Allow GRR for single inbound deliveries.

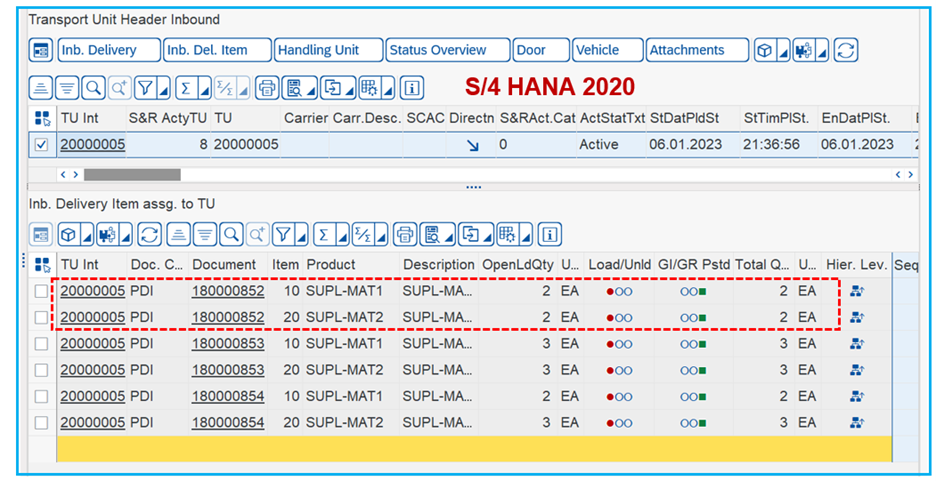

In the below example, a transportation unit(20000005) is assigned to 3 Inbound deliveries ending with 852, 853 & 854 and GR is posted at TU level resulting in 1 EWM warehouse document.

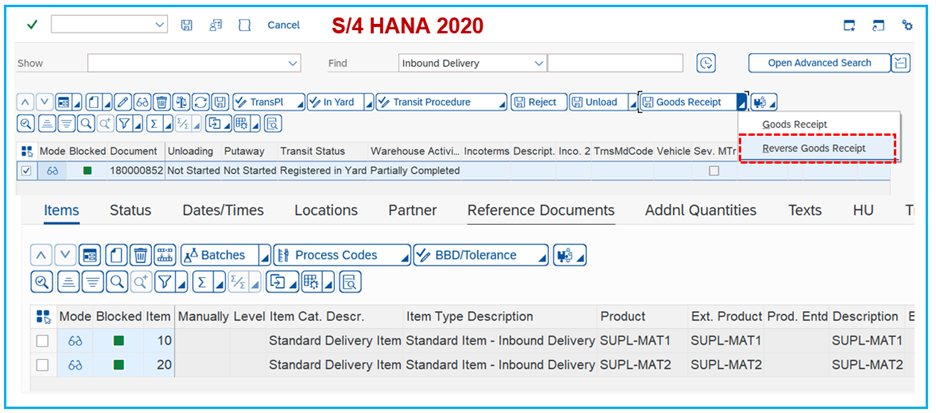

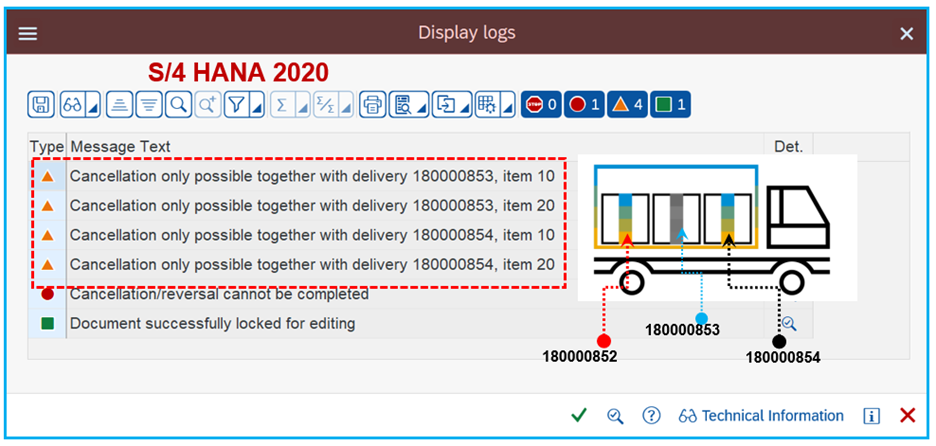

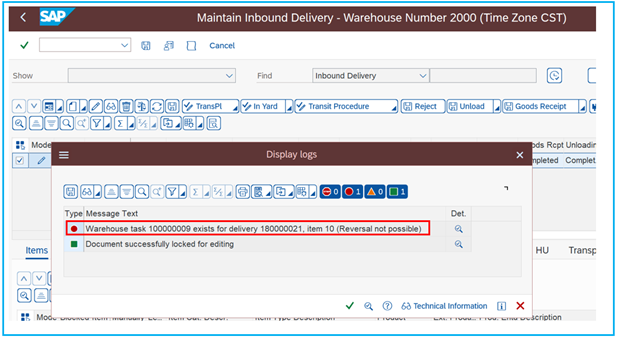

If it is required to conduct GRR at partial Inbound delivery, e.g. for IBD ending with 852, SAP ends up in error as below Prior to S/4 HANA EWM 2021 FPS1.

Partial cancellation was disallowed as the system was expecting group cancellation of all other inbound deliveries, which is a tedious process for the business if a truck contains a very large number of Inbound deliveries.

In the below example, the system is reading other inbound deliveries ending with 853 & 854 beside the inbound delivery in question 852 relevant for GRR.

With S/4HANA 2020 FPS1, partial cancellation of inbound delivery is very much possible and the process of GRR is shortened to a great extent (as depicted in the below diagram).

Scenario-I : GRR at PDI header level

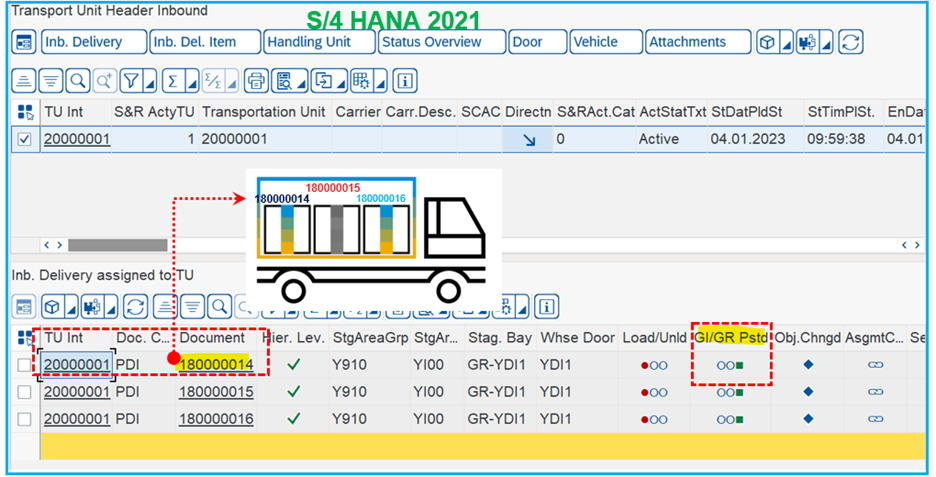

Lets take an example in the S/4 HANA 2021 system. A trailer is assigned to three inbound deliveries ending with 014, 015 & 016. Inbound delivery 014 is relevant for partial cancellation as this delivery is not available in trailer during physical verification done by the warehouse operator during unloading of the TU docked at the door.

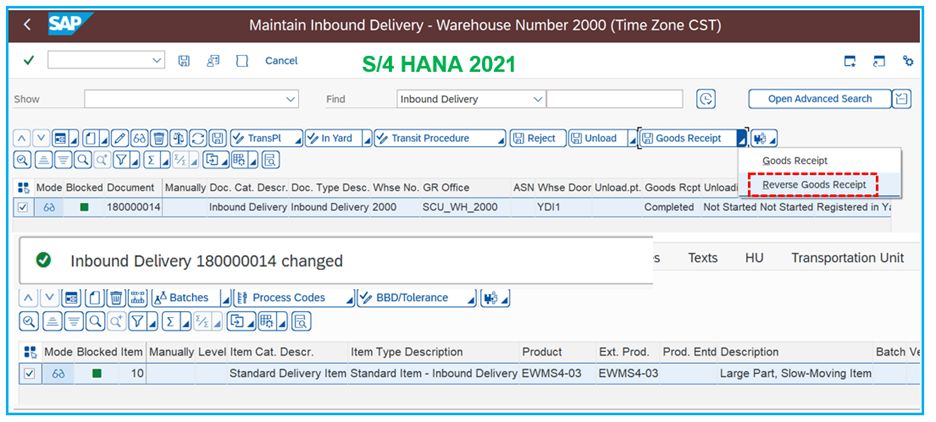

Perform the Goods Receipt reversal (GRR) for this Inbound delivery 180000014. System allowed to perform the reversal at partial delivery level.

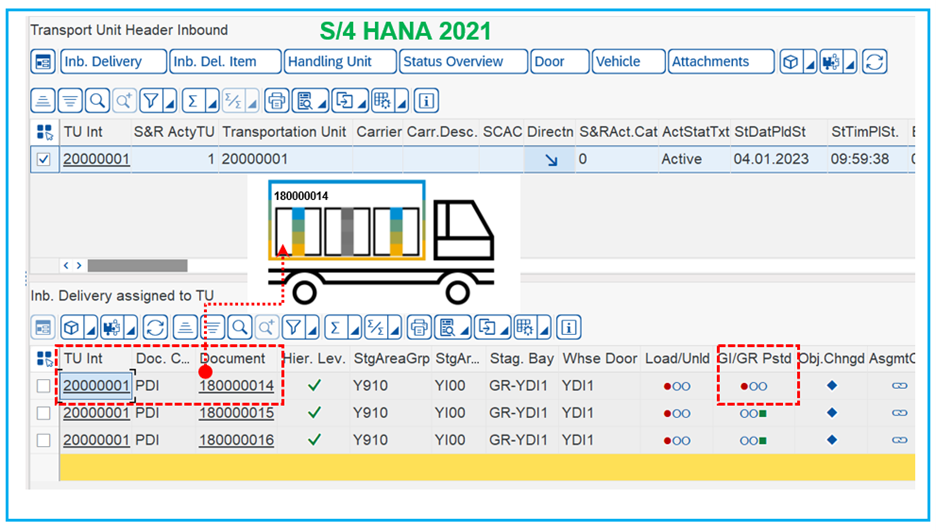

In the below example, inbound delivery 180000014 GR status is reversed while the other two inbound deliveries 180000015 and 180000016 have status as GR posted. Only the missing delivery in trailer has been reversed.

Scenario II:GRR at HU level.

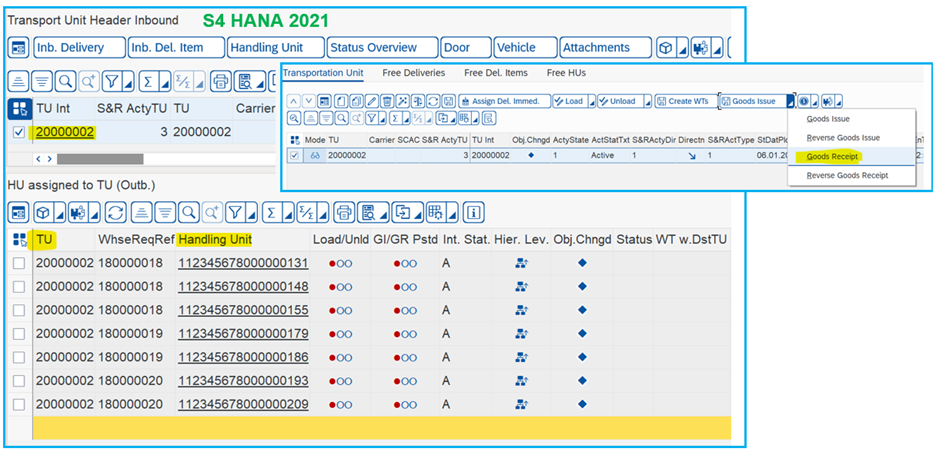

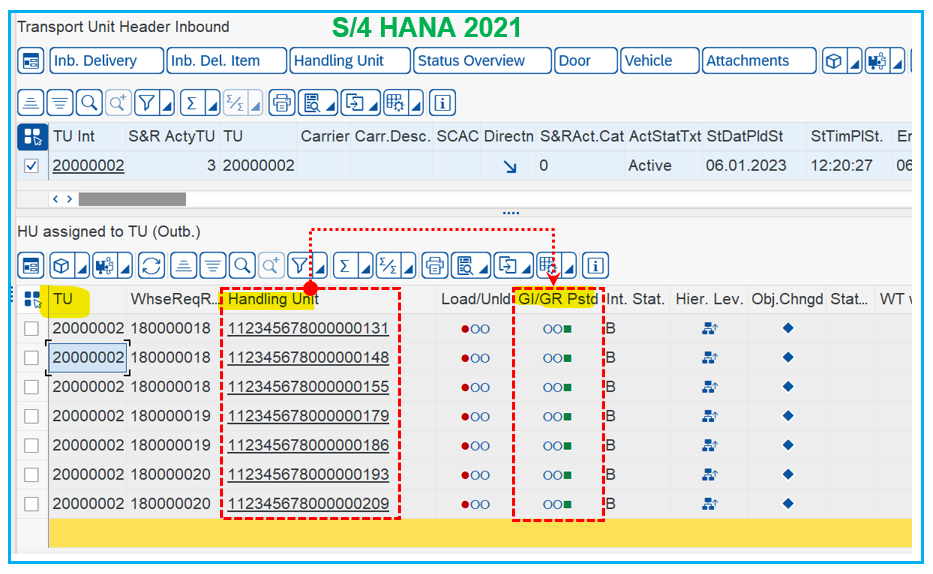

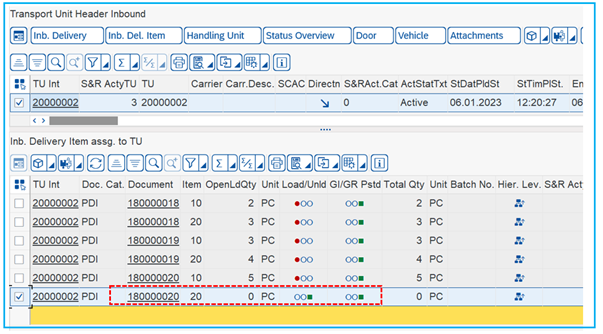

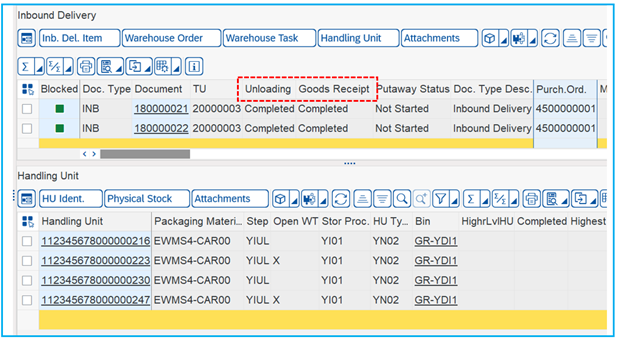

A TU 20000002 is assigned to three inbound deliveries ending with 018, 019 & 020 with corresponding HUs.

Perform GR at TU level so that all deliveries and HUs will be GR posted as highlighted.

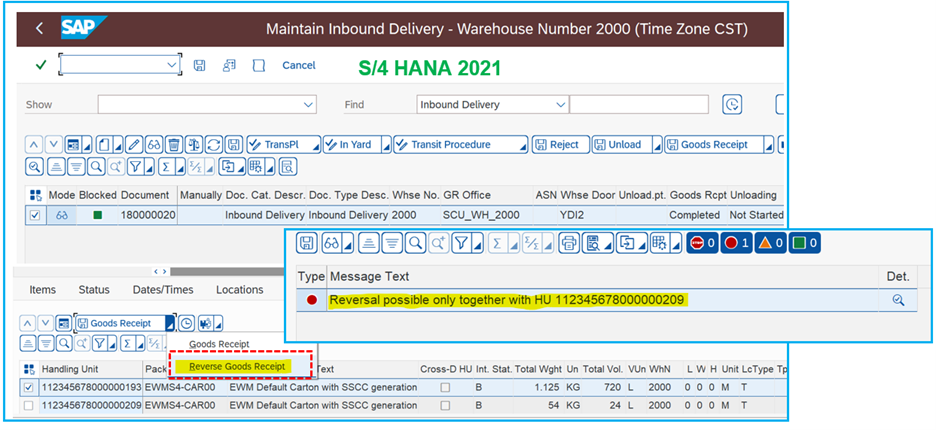

Try to perform GR reversal at HU (HU ending with 193) level as below for Inbound delivery 180000020. System prompts a message stating reversal to be conducted with other HU ending with 209, meaning GRR to happen at Inbound delivery level.

Reason for error: If inbound deliveries contain handling units, the Partial Goods Receipt reversal at HU level is not possible – business must perform GRR at Inbound delivery level assigned to relevant HUs.

Alternative solutions to allow GRR at HU level:

Solution I

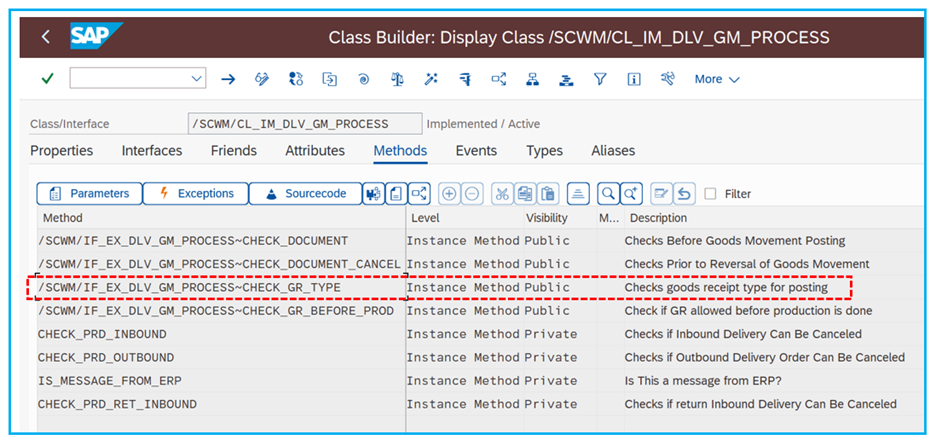

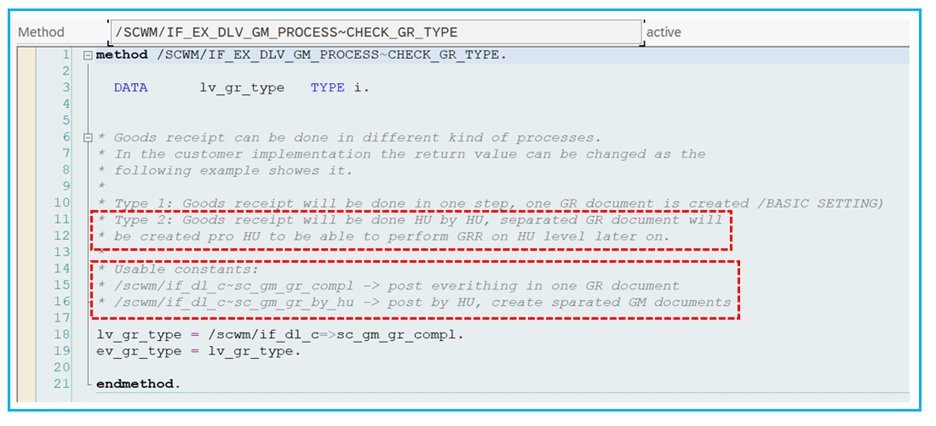

In this case, if it is required to perform GRR at HU level, business has to implement a Badi /SCWM/EX_DLV_GM with Method /SCWM/IF_EX_DLV_GM_PROCESS~CHECK_GR_TYPE.

By changing the flag in a custom implementation the goods receipt mode can be changed in order to receipt on handling unit level, one by one. Instead of calling the goods movement for each handling units, with this solution the goods receipt will be done in one step, but each handling unit will get own goods movement document. This will help to reverse the goods receipt individually pro handling unit later on.

Solution II

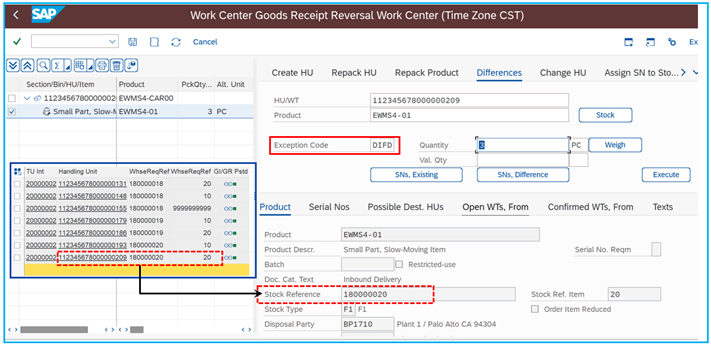

To perform GRR at HU level clubbed with multiple inbound deliveries in a TU can be conducted using exception code DIFD using a Goods receipt reversal work centre.

Inbound delivery is zeroed out and HU reference is deleted when quantity is updated as zero in difference section of /SCWM/PACK. This will allow correct pallet to be received into warehouse.

Scenario III:

GRR after Complex Unloading.

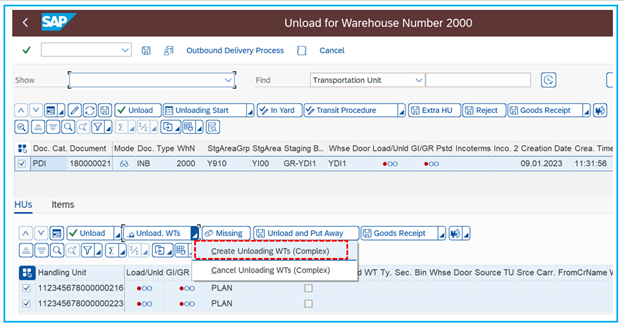

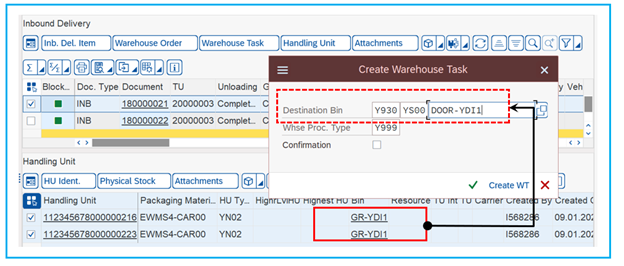

In a complex unloading process or 2 step Inbound process (Unload+ Putaway POSC), when HUs are unloaded and HUs are moved to Staging area via HU WT, let’s check how GRR can be performed.

Unloading & GR Status = Completed

Let’s try to perform GR reversal.

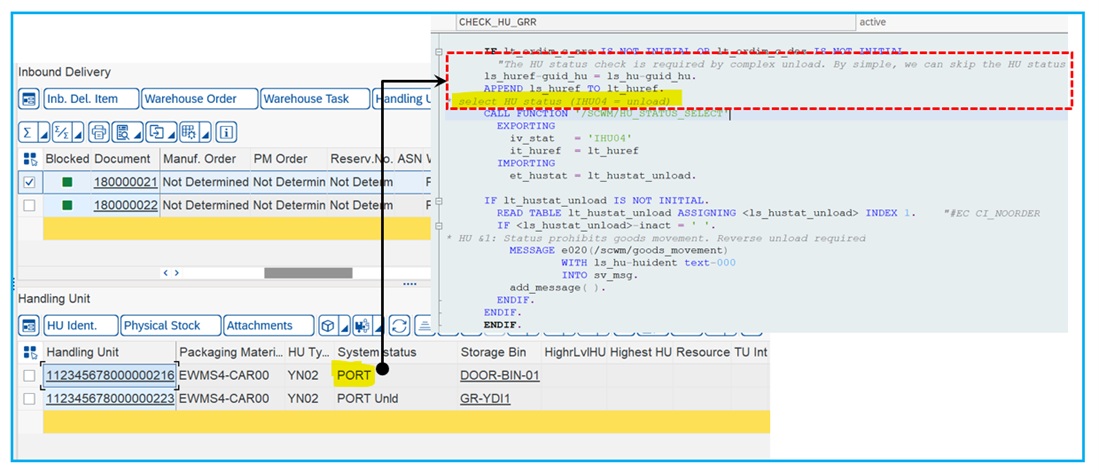

System triggers an error if GR reversal is performed after performing Complex unloading.

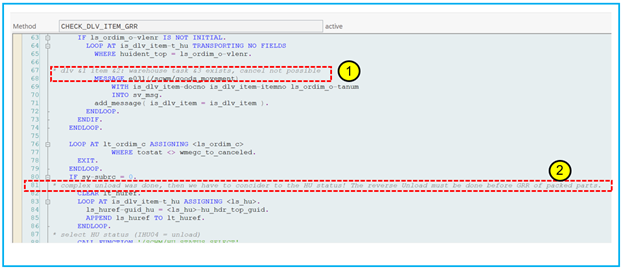

Debugging the error, there are some pre-requisites to allow GRR after complex unloading as per code.

• There should be no open WT connected to stock which needs to be reversed.

• If complex unloading is done, reverse unloading needs to be performed.

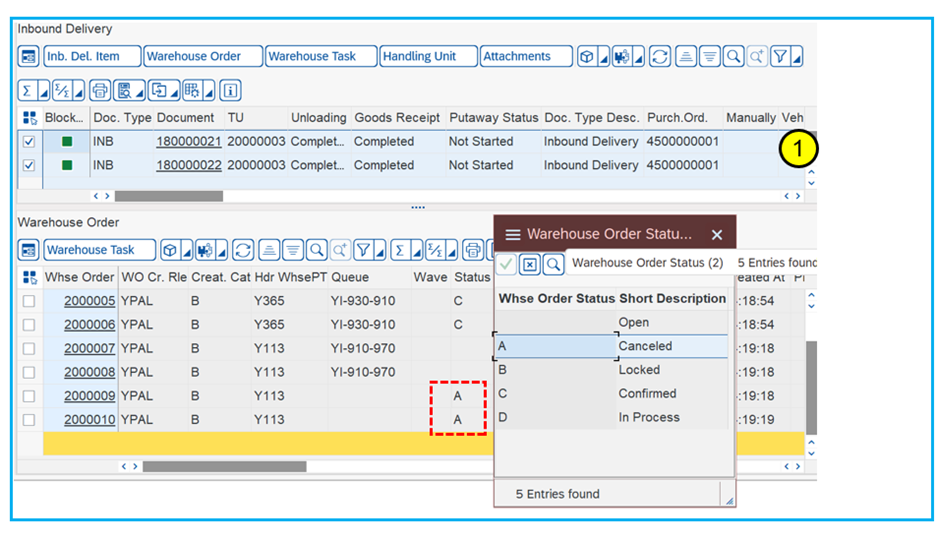

1. Cancel the existing open HU WT.

2. Perform Reverse Unloading.

Note: HU status is reset to ‘Port’ to allow GRR at PDI header level. Create HU WT for the other HU as well from Staging area to Door Bin(TU) to reset complex unloading status and then system will allow GRR.

General restrictions of GRR:

– There should be no open warehouse task connected to the stock to be reversed

– The reverse unloading needs to be done before GRR for complex unloaded stocks

– The goods receipted stock’s content should not be changed. It means that the stock should be in the GM bin or on the truck, or should not be moved back meanwhile. In addition, the content should be identical: HU hierarchy, stock type, quantity, Repacked, unpacked, or any kind of packaging should not happen

– Goods receipt correction should not be performed –usually by unloading WT confirmation

– The stock should not be putaway

– The delivery item should not be relevant for inspection planning.

Author: Shailesh Mishra, Senior Consultant SAP EWM