Cartonization Planning (CAP) in Decentralized SAP SCM EWM 9.5

Cartonization Planning (CAP) in Decentralized SAP SCM EWM 9.5.

Cartonization Planning (CAP)

• Cartonization planning is to improve the creation of shipping handling units (HUs) based on information from product master data and outbound delivery orders, such as quantities, volume, and weight.

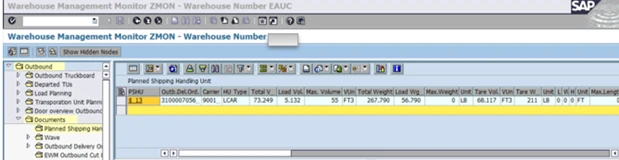

• Cartonization planning results in the creation of planned shipping handling units (PSHUs) that you can use as templates for creating shipping HUs during picking or packing.

• A PSHU is an object like a shipping HU, describing a packaging material and the items it contains. In contrast to a shipping HU, a PSHU does not physically exist in the warehouse and is only used to plan shipping HUs.

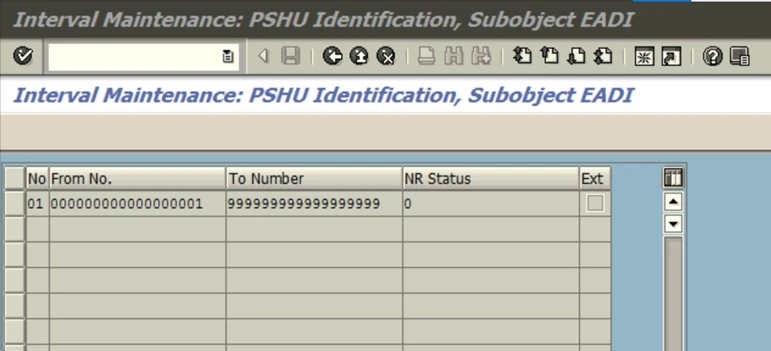

• A PSHU is identified by an 18-digit number with the prefix $_.

• PSHUs can be created manually (/SCWM/CAP) and automatically (Algorithm) in Cartonization planning.

• Functionality of Cartonization is available with both Decentral and Embedded EWM. However, embedded EWM requires additional license to use Cartonization.

• You must activate the business function EWM, Essential Foundation Functions (SCM_EWM_FND).

Configuration steps

01: Define Process Profiles for Cartonization Planning

02: Determine Process Profiles for Cartonization Planning

03: Define Number Ranges for Identification of PSHUs

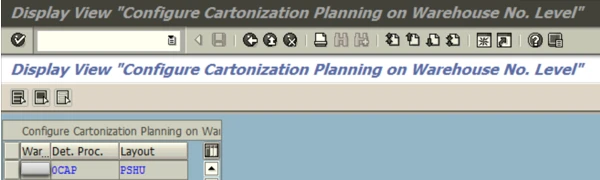

04: Configure Cartonization Planning on Warehouse Number Level

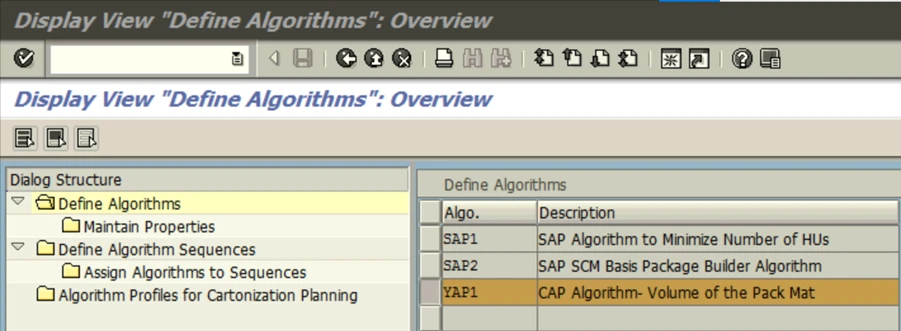

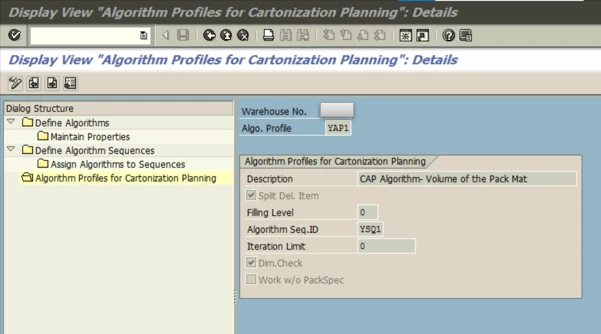

05: Define Algorithm Profiles for Cartonization Planning

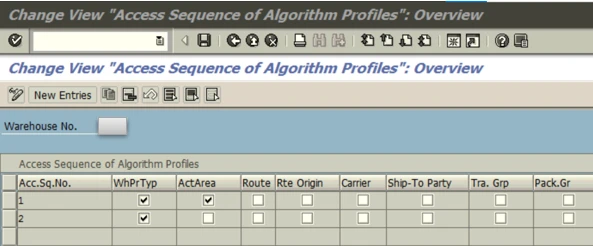

06: Define Access Sequence of Algorithm Profiles

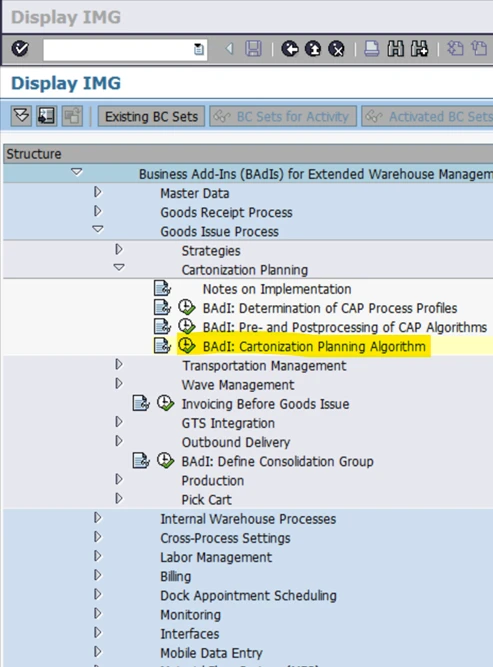

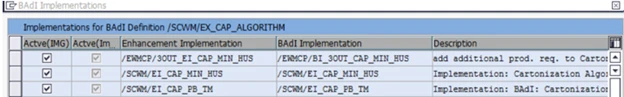

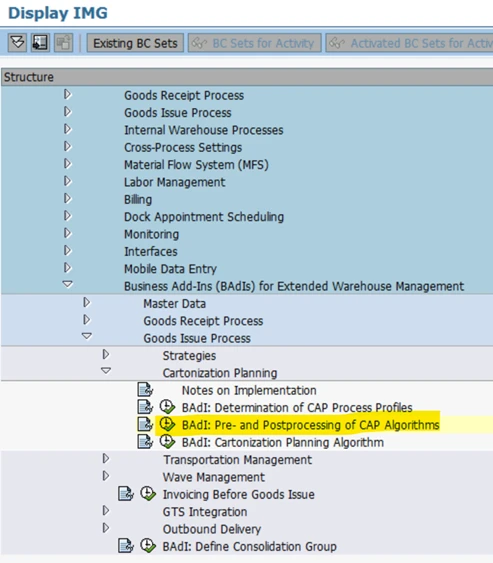

07: For Automatic Cartonization planning, you must activate BADI method Execute.

Master Data:

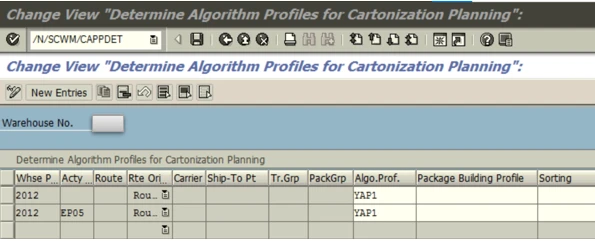

01: Determine Algorithm Profile T-Code: /SCWM/CAPPDET

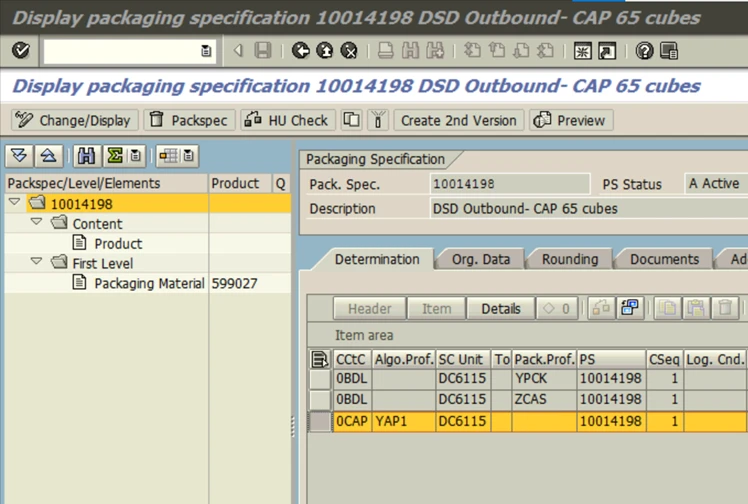

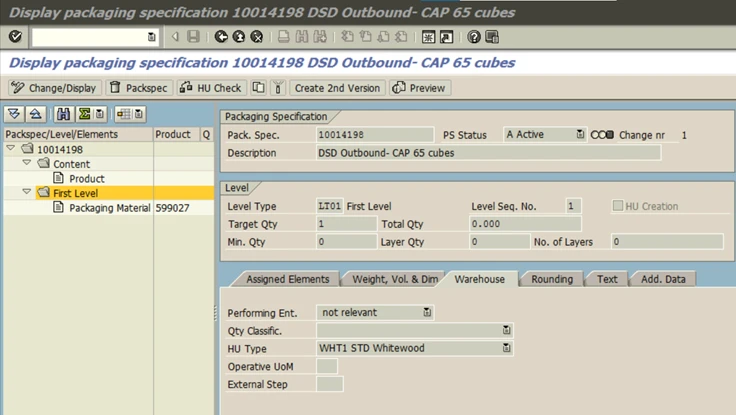

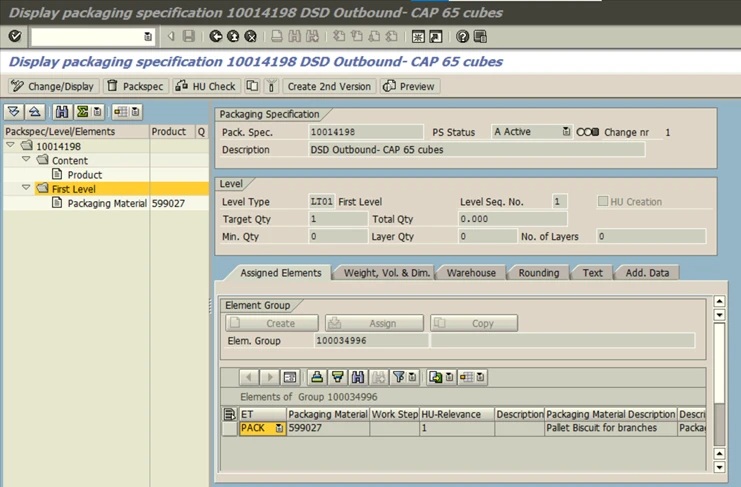

02: Define Pack Spec T-Code: /SCWM/PACKSPEC

03: Define a start and end bin for the activity area T-Code: /SCWM/SEBA

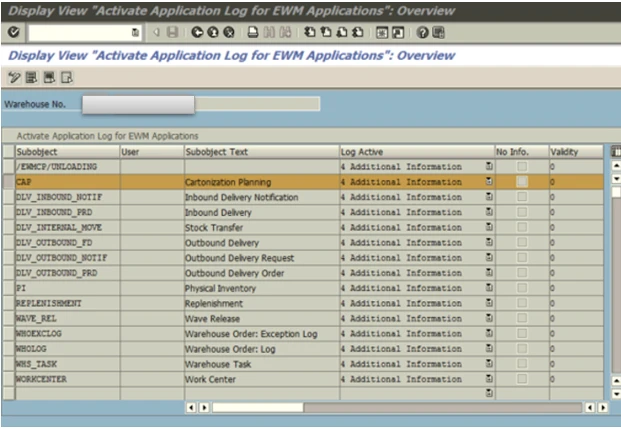

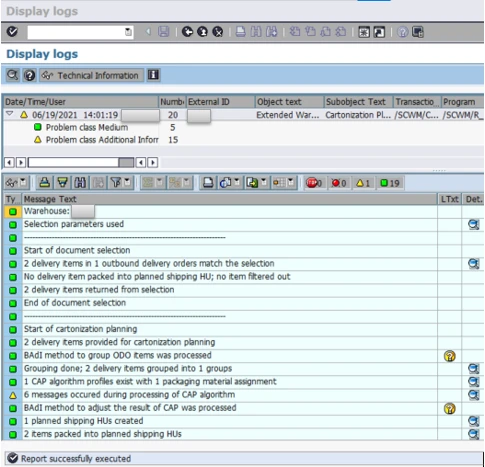

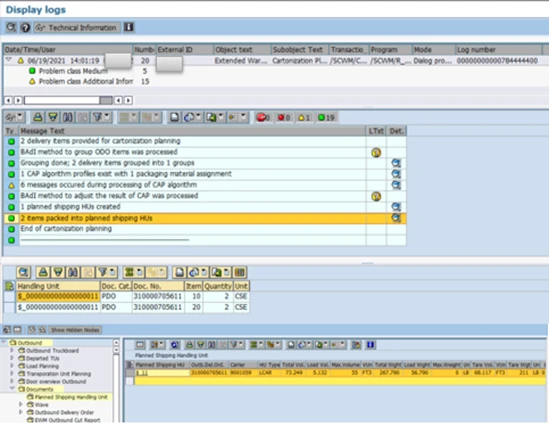

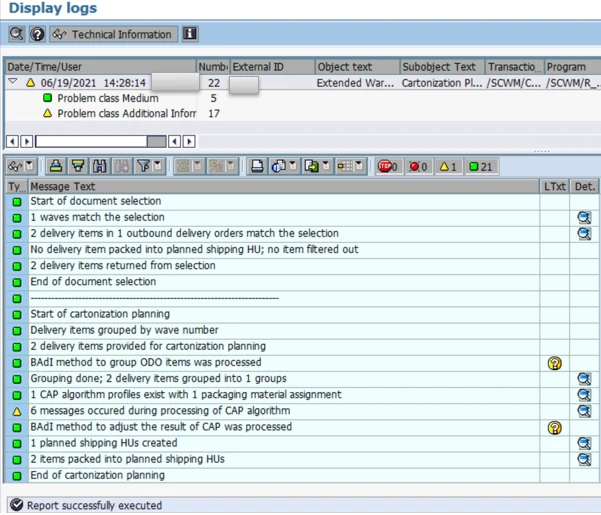

04: Activate Log for Cartonization Planning T-Code: /SCWM/ACTLOG

Configuration steps:

Prerequisites for Cartonization Planning.

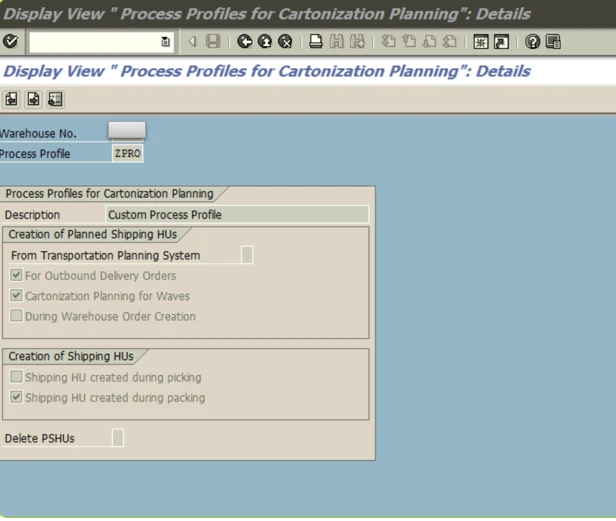

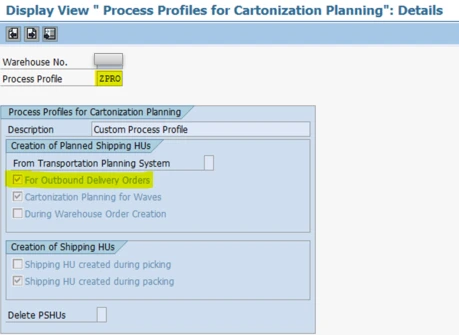

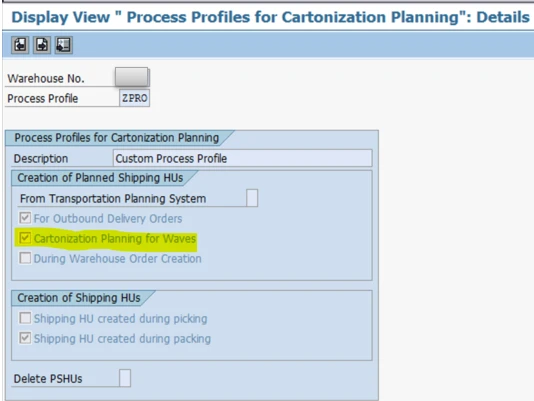

01: Define Process Profiles for Cartonization Planning

Process profile in Cartonization planning to determine when in the outbound process planned shipping HUs are created and used for the creation of shipping HUs.

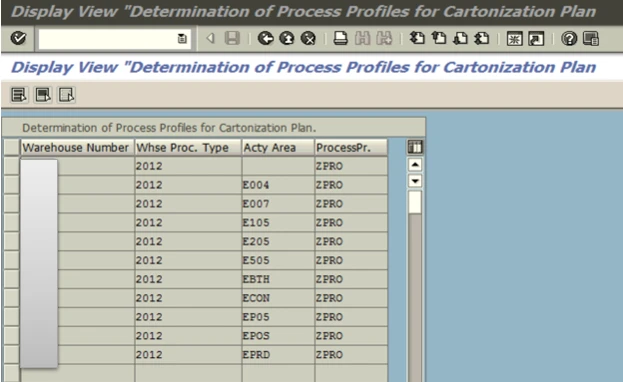

02: Determine Process Profiles for Cartonization Planning

03: Define Number Ranges for Identification of PSHUs

04: Configure Cartonization Planning on Warehouse Number Level

05: Define Algorithm Profiles for Cartonization Planning

Algorithm profile used by the system in the process of Cartonization planning to determine the way the system creates planned shipping HUs.

06: Define Access Sequence of Algorithm Profiles

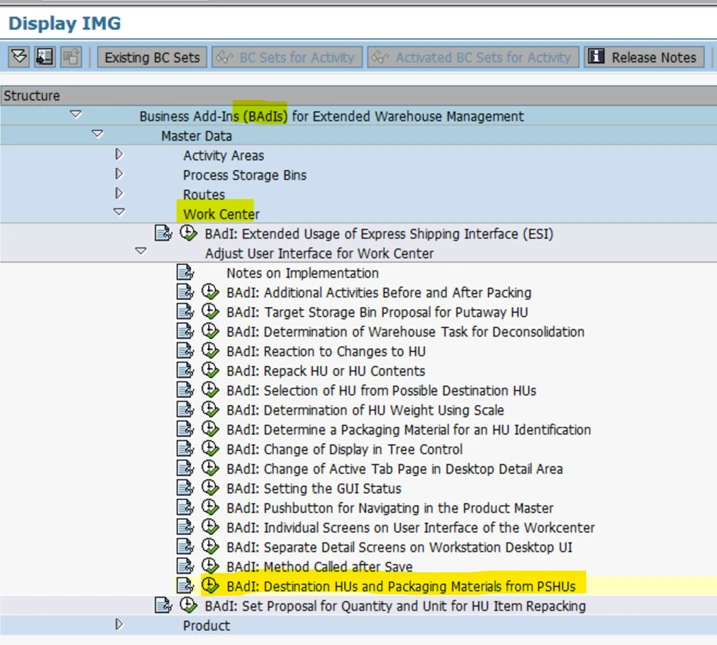

07. For Automatic Cartonization planning, you must activate BADI method Execute.

BADI Implementation: Here we can add custom code to create PSHU based on business need.

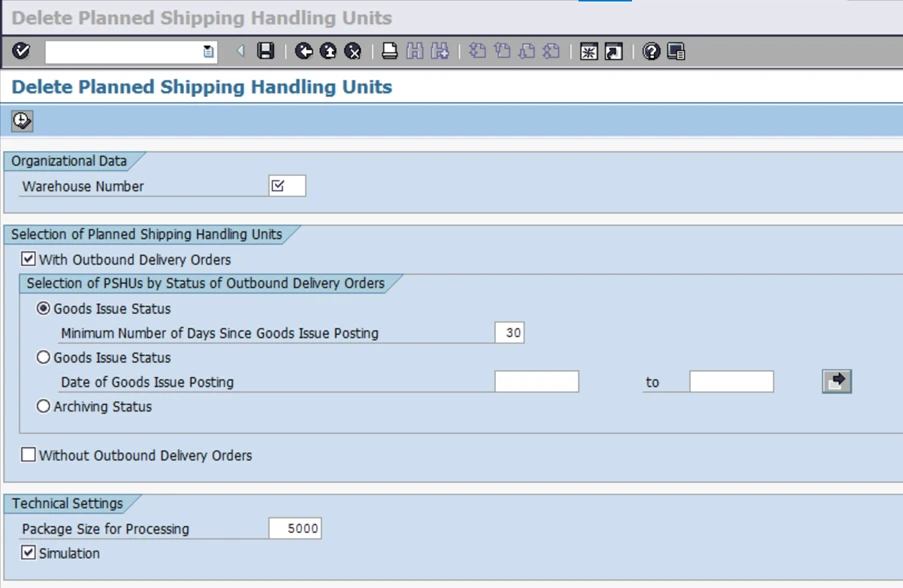

Note: SAP recommend deleting obsolete PSHUs regularly i.e., those items are already goods issue.

T-code: /SCWM/CAPDEL - Delete Planned Shipping Handling Units or schedule the report/SCWM/R_CAP_DELETE for background Job.

Master Data

T-code: /SCWM/CAPPDET

T-code /SCWM/PACKSPEC

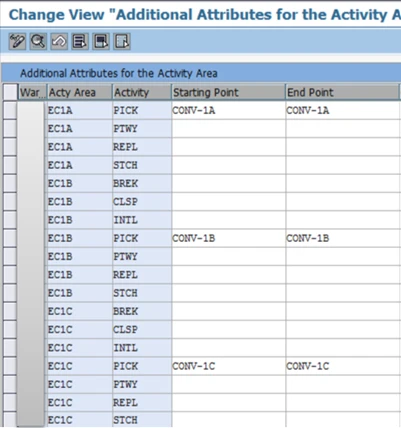

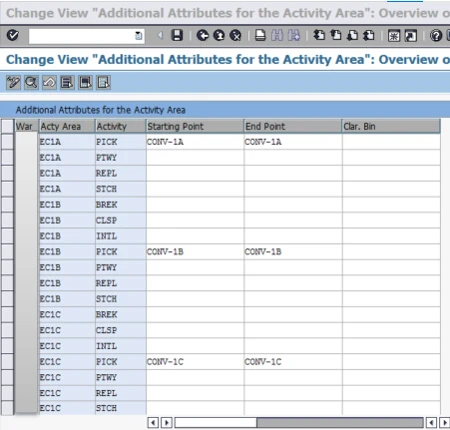

T-code: /SCWM/SEBA

T-Code: /SCWM/ACTLOG

The system groups outbound delivery order items that are to be packed together during Cartonization planning; the system processes each group independently of other groups. Delivery items from different groups are not planned to be packed together in the same HU. The grouping depends on the following criteria:

1. Algorithm profile for Cartonization planning

2. Consolidation group

3. Activity area

4. Wave (in case of Cartonization planning for waves only)

The following prerequisites are optional:

• To modify the standard grouping of outbound delivery order items before executing the Cartonization planning algorithms, you have implemented the BADI method GROUP_ITEMS.

• To modify the result of the Cartonization planning algorithms, you have implemented the BADI method ADJUST_CAP_RESULT.

Automatic Cartonization planning has the following variants:

• Cartonization Planning for Outbound Delivery Orders

• Cartonization Planning for Waves

• Cartonization Planning During Warehouse Order Creation

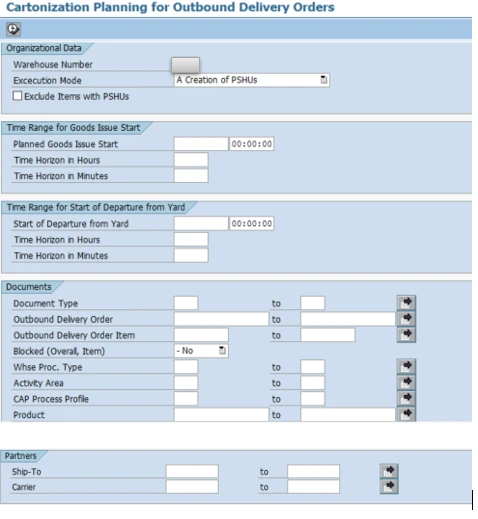

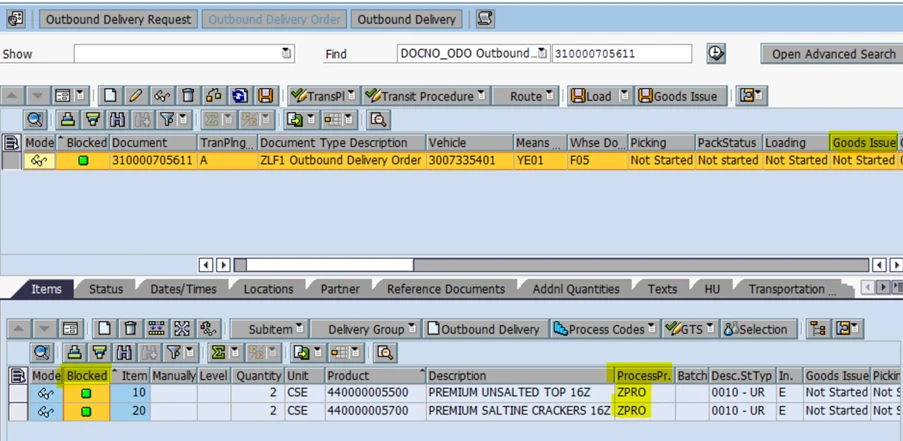

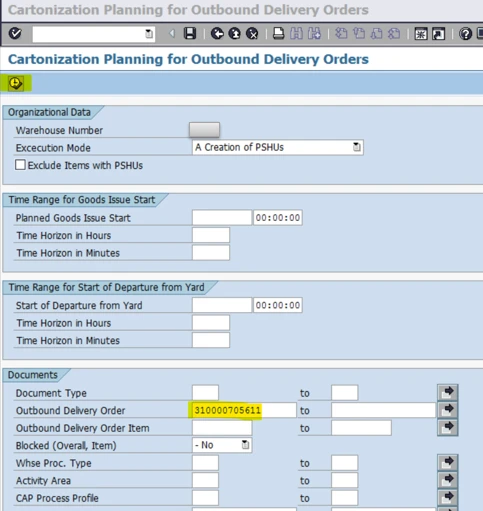

1.Cartonization Planning for Outbound Delivery Order.

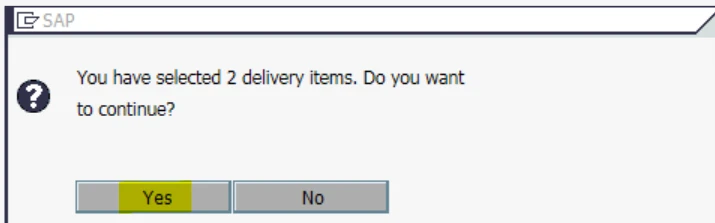

You can use this function of automatic Cartonization planning to have the system create planned shipping handling units (PSHUs) for outbound delivery orders based on predefined algorithms.

In this use case, you work without waves. The system automatically creates PSHUs for outbound delivery orders. The system uses the PSHUs as templates for proposing packaging materials or destination HUs during packing at the work center or using RF. This enables early planning of shipping HUs.

Features

Selection of Outbound Delivery Orders for Cartonization Planning. You can select outbound delivery orders by the following criteria:

1. Organizational data: warehouse number

2. Time range for planned goods issue start

3. Time range for planned start of departure from yard

4. Document data

5. Partner data

T-code: /SCWM/CAPDLV

Selection of Outbound Delivery Order Items for Cartonization Planning:

1. The delivery item has the status Blocked (Unchecked Item) with an initial value, which means that the item is not blocked.

2. The delivery item has the status Goods Issue with value Not Started.

3. The delivery item has a process profile for Cartonization planning in which the checkbox Create Planned Shipping HUs for Outbound Delivery Orders is selected.

Execution Mode

Besides creating PSHUs, you can also use this function in the following execution modes:

1. Simulation

In simulation mode you can test Cartonization planning without creating PSHUs in the database.

2. Deletion

If you have already carried out Cartonization planning, you can delete the existing PSHUs before starting Cartonization planning for outbound delivery orders.

Activities

To start Cartonization planning for outbound delivery orders, execute the transaction T-code: /SCWM/CAPDLV

or schedule the report in background /SCWM/R_CAP_BACKGROUND.

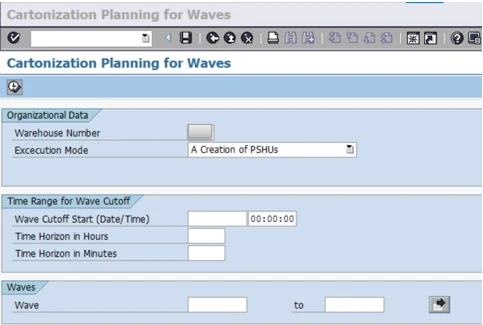

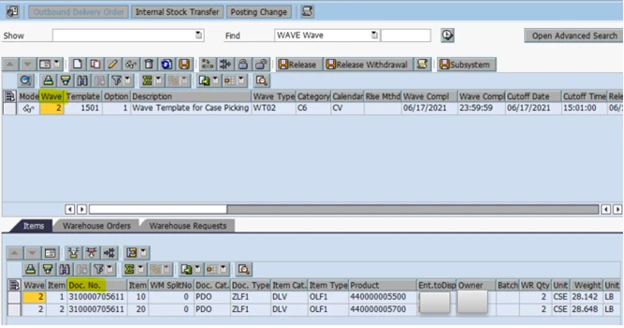

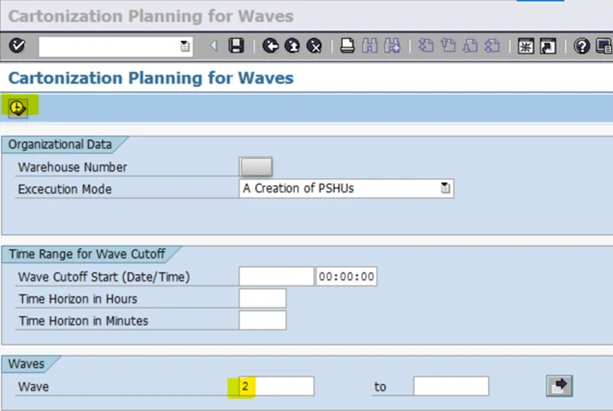

2.Cartonization Planning for Waves

You can use this function of automatic Cartonization planning to have the system create planned shipping handling units (PSHUs) for waves based on predefined algorithms.

In this use case you work with waves. The system automatically creates PSHUs for waves. The system uses the PSHUs as templates for proposing packaging materials or destination HUs during packing at the work centre or using radio frequency (RF).

Features

Selection of Waves for Cartonization Planning. You can select waves by the following criteria:

3. Organizational data: warehouse number

4. Wave Cut-off date and time

5. Wave number

T-code: /SCWM/CAPWAVE

Selection of Outbound Delivery Order Items for Cartonization Planning

When you start Cartonization planning for waves, the system selects outbound delivery order items that fulfil the following criteria:

1. The delivery item is assigned to the selected wave.

2. In case of split items, the split item is assigned to the selected wave.

3. The delivery item has a process profile for Cartonization planning in which the checkbox Create Planned Shipping HUs for Waves is selected.

Activities

To start Cartonization planning for waves, execute the transaction Cartonization Planning

T-code: /SCWM/CAPWAVE

or schedule the report in background /SCWM/R_CAP_WAVE.

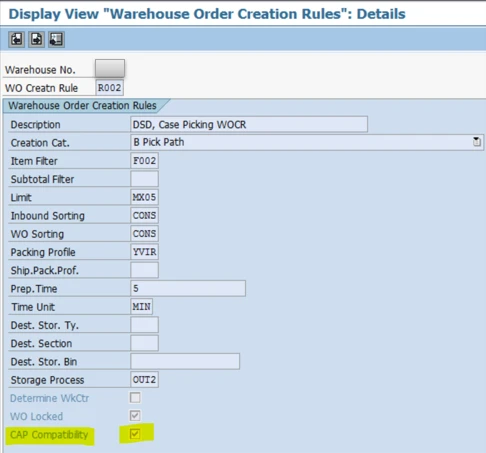

3.Cartonization Planning During Warehouse Order Creation

You can use this function of automatic Cartonization planning to have the system create planned shipping handling units (PSHUs) for pick-warehouse tasks (WTs) during warehouse order (WO) creation. The system uses the PSHUs as templates to create shipping HUs during either picking or packing.

Picking with automatic Cartonization planning for warehouse tasks during warehouse order creation:

In this case you work with waves. The system automatically creates planned shipping handling units (PSHUs) for warehouse tasks during warehouse order creation. The system uses the PSHUs as templates for creating pick-handling units (pick-HUs), which you use as shipping handling units (shipping Hus)

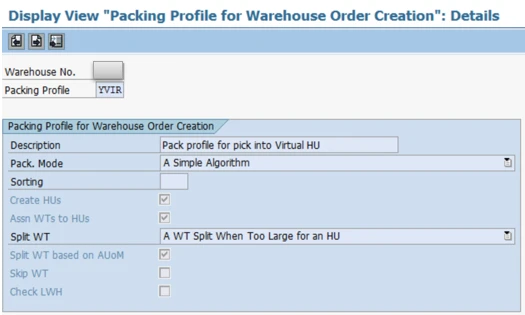

Prerequisites

For picking with Cartonization planning, the following prerequisites must be met:

1. To enable the use of a warehouse order creation rule for Cartonization planning, you have selected the CAP Compatibility checkbox of the rule.

2. You have defined warehouse order creation rules for picking from the activity areas.

3. So that the packing profile in the warehouse order creation rule creates the pick-HUs, you have selected the Create HUs and the Assign WTs to HUs checkboxes in the packing profile.

4. You have defined a start and end bin for the activity area. If you use a pick point, the bin of the pick point is the starting bin of the activity area.

Note: Picking with Cartonization planning is also possible when using pick points

Two-Step Picking

In two-step picking, the warehouse tasks for withdrawal have no reference to outbound delivery orders. For this reason, you cannot use picking with Cartonization planning in the withdrawal step. However, you can use picking with Cartonization planning in the allocation step.

Packing with automatic Cartonization planning for warehouse tasks during warehouse order creation:

In this use case you work with waves. The system automatically creates PSHUs for warehouse tasks during warehouse order creation. The system uses the PSHUs as templates for proposing packaging materials or destination HUs during packing at the work center or using RF.

Prerequisites

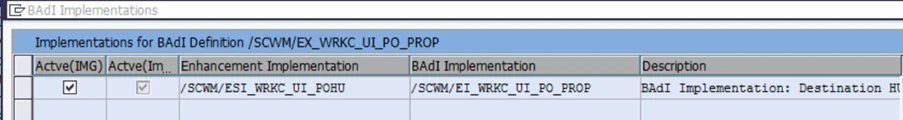

You have implemented the Business Add-In BAdI: Destination HUs and Packaging Materials from PSHUs or use the default implementation.

Features

The destination HUs or packaging materials proposed by the system depend on the implementation of the BAdI: Destination HUs and Packaging Materials from PSHUs. The default implementation /SCWM/ESI_WRKC_UI_POHU aims at emptying the pick-HUs as soon as possible. You can also implement the BAdI in a way that the shipping HUs become completely packed as soon as possible.

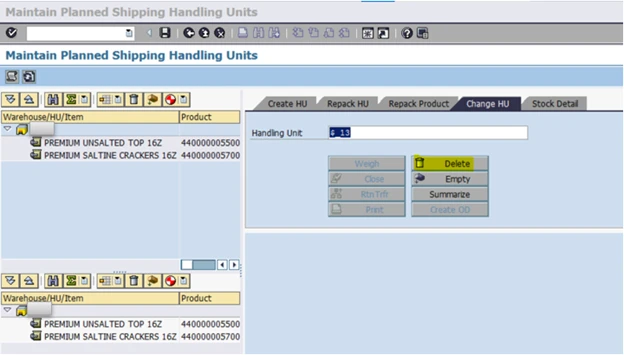

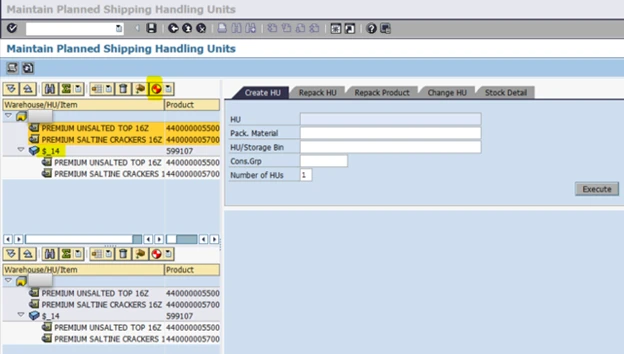

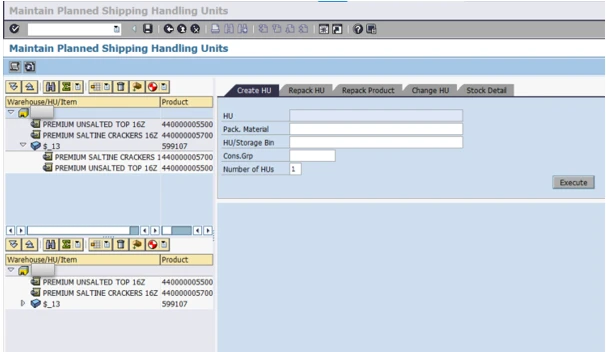

Maintenance of Planned Shipping Handling Units

You can use this function of Cartonization planning to carry out the following tasks:

1. Display the result of a previous Cartonization planning

2. Change the result of a previous Cartonization planning manually to handle exceptional situations e.g. if pick denial reduced, delivered quantity or delivery items are to be shipped with other transportation units.

3. Simulate or carry out automatic Cartonization planning (see Automatic

Cartonization Planning) for selected unpacked outbound delivery items to test, for example, different algorithm.

Prerequisites

1. You have specified a work centre layout for Cartonization planning.

2. You have selected a work center layout for your warehouse number.

Activities

To maintain PSHUs use T-code /SCWM/CAP

On the selected delivery items, you can carry out the following activities:

1. Create PSHUs

2. Repack PSHUs

3. Repack products

4. Change PSHUs

5. Display stock data

6. Start automatic Cartonization planning

To do so, select an unpacked delivery item with an open quantity greater than zero and choose Automatic Cart. Planning. The system automatically determines the algorithm profile for Cartonization planning.

Simulate automatic Cartonization planning-To do so, select an unpacked delivery item with an open quantity greater than zero and choose Test Cart. Planning. You can manually select the algorithm profile for Cartonization planning.

We will Unpack the existing PSHU and use automatic option to recreate the new PSHU.